In the pursuit of productivity

The domestic freight transport industry of the 21st century is a very demanding one. Whether it’s by road that goods are transported, ultimately the same commercial considerations apply.

Generally speaking each mode has tended to be restricted to the domains where their relevance is clearly established. For example, high volume bulk construction products such as spoil and aggregates, which require a more massive transport solution, lend themselves to rail rather than road, whereas palletised goods will be more often transported by truck. Where rail does feature in the palletised goods supply chain, the ‘last mile’ is, more often than not, still undertaken by road.

With a fleet that today exceeds 16,000 rail wagons, the 4th largest in Europe, Wascosa understands that the rail market has to evolve its offering to the wider logistics market; to create effective, sustainable and attractive solutions to extend rail’s reach, to develop concepts that integrate with other transport modes and add value to the end logistics process . At Wascosa the thinking was that the ingredient that was missing from the formula and which would be the key to increased productivity was – Innovation.

Modular concept

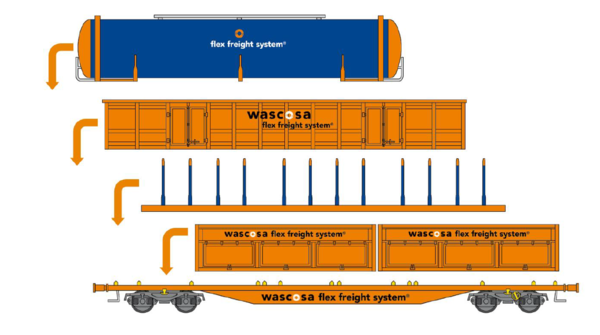

The challenge was to solve the equation between innovation and productivity with a solution that would save resources, time, and money. In 2009 Wascosa found the answer and the award winning flex freight wagon system® was born.

Foto: Wascosa AG

As its name suggests, it’s a modular concept which allows flexible utilisation of a container flat wagon with a variety of superstructures that can be mounted on top according to the type of product to be transported, increasing the flexibility of the use of the base rail wagon, increasing its productive use and thus reducing its operating cost.

For example, with its fold-away and full stackable stanchion cassettes, the system can be deployed for the transportation of timber or pipes but can be quickly converted to carry wood chippings, scrap metal, steel products or waste paper using another type of superstructure e.g. the flex freight E-type swap body, which is a modular box with four double doors and a steel floor.

Foto: Wascosa AG

Other modular superstructures also exist for transporting vehicles as well as automotive parts and the flex freight system® is also compatible with most types of ISO containers and tank containers.

The superstructure configuration possibilities are virtually endless, subject to any design conforming to ISO standards, to maintain rail gauge integrity.

Several hundred of these modular freight wagons are now in service across the continent, notably with German chemical giant, BASF, but also with the Swiss based infrastructure company SERSA. Network Rail will take delivery of 260 flex freight wagons in the 12 months from November this year, already with further superstructure options under consideration.

Foto: Wascosa AG

The obvious advantage over traditional dedicated wagons is that more types of cargo can be transported using fewer wagons which in turn can achieve more loaded journeys during their operating life cycle, ultimately meaning a more efficient utilisation of the wagon fleet as well as a lower investment risk.

By virtue of its adaptability the flex freight system® also opens up the possibility of transporting two different types of cargo back and forth on a given route thus avoiding unproductive empty running which is a major cost factor in dedicated trainload configurations. Also, because of the intermodal capability of superstructures such as open boxes and ISO containers, flex freight can serve non-rail connected, inner-city destinations, without the need for time consuming and problematic transhipment operations that would be required in the case of traditional rail wagons.

Foto: Wascosa AG

By its very nature flex freight is more productive because of its suitability to seasonal and cyclical fluctuations and also offers a better cost to performance ratio in terms of repairs and servicing. This is because the flex freight system® has a higher standardization of critical components making it easier and faster to maintain which in turn means less downtime and lost revenue because if the modular superstructure is damaged in any way it can simply be replaced without the whole wagon having to go to a repair shop.

A change of superstructures is undertaken easily and quickly with a forklift / handler, minimising wagon downtime and eliminating the need for separate pools of single use wagons.

TELEMATICS – The Brain in the Train

Foto: Wascosa AG

The advent of telematics, or the ability to convey wagon related data from on-board sensors via GPS technology, has the potential for improving rail performance levels immeasurably and is already heralding the end of manually inputted information with all the human errors that this can entail.

That’s why Wascosa has invested massively with its partner kasasi GmbH in a state of the art telematics suite which uses self-learning based on algorithms and Artificial Intelligence for predictive wagon management. Not only are the sensors able to provide information on the geographical location and behaviour of the wagon, but they can take over the task of measuring automatically the performance of critical wagon components such as braking systems, axles and wheel sets with infallible precision.

There can be no doubt as to the advantages with respect to wagon availability that the power of data analysis of wagon performance can provide in terms of managing events pro-actively rather than re-actively and that is why Wascosa is convinced that the future belongs to automated train and wagon inspection and management systems.

The smart wagon is already here and it’s part of the vision which has enabled Wascosa to progress from being the 4th wagon rental company on the continent to Europe’s first provider of freight wagon systems.