We’ve all heard of the terminologies “building back” and “levelling up” which have become the “brand” names for the government’s policies on meeting the challenges posed by Brexit and for steering the country out of the pandemic.

But what we are no doubt less aware of are the mechanics of how these policies apply to the country’s infrastructure and skills base and what effect they have had on the industrial sectors that power our economy.

In the transport industry at least, rail freight has become a major driver of the UK’s recovery from the Covid by providing a more reliable and ecological alternative to all too many trucks and trailers which clog up the country’s roads and motorways. Indeed it is estimated that the equivalent of 7 million HGV loads have shifted to rail in the last year alone with the principal beneficiary being containerised traffic. As fuel prices continue to rise and concerns over the effects of climate change hit home this trend is set to continue.

So a transitional dynamic is now firmly established and with demand for rail based transport solutions, in many cases, outstripping supply especially in terms of intermodal wagons, there has seldom been a better opportunity for innovative rail freight systems to make the leap from a niche concept to a mainstream solution.

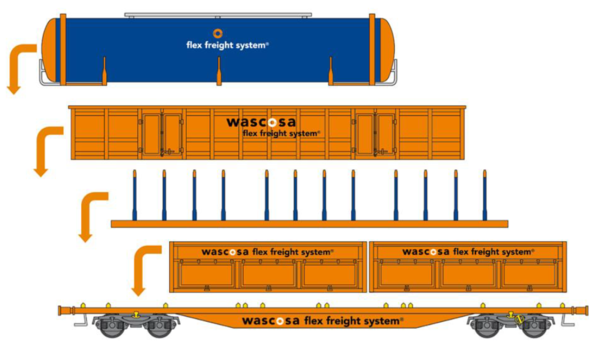

For there is now a growing consensus that a more agile, economic and productive alternative to the traditional single purpose dedicated wagon is needed and this new departure is what the flex freight system®, developed by Wascosa, Europe’s largest independent wagon leasing company, with its fleet of 16000 wagons, is all about.

Photo: Wascosa AG

As its name suggests, Wascosa flex freight system® is a modular concept which allows flexible utilisation of a container flat wagon with a variety of superstructures that can be mounted on top according to the type of product to be transported, increasing the flexibility of the use of the base rail wagon, increasing its productive use and thus reducing its operating cost.

For example, with its fold-away and full stackable stanchion cassettes, the system can be deployed for the transportation of timber or pipes but can be quickly converted to carry wood chippings, scrap metal, steel products or waste paper using another type of superstructure e.g. the flex freight system® E-type swap body, which is a modular box with four double doors and a steel floor.

Other modular superstructures also exist for transporting vehicles as well as automotive parts and the Wascosa flex freight system® is also compatible with most types of ISO containers and tank containers. The superstructure configuration possibilities are virtually endless, subject to any design conforming to ISO standards, to maintain rail gauge integrity.

Photo: Wascosa AG

Several hundred of these modular freight wagons are now in service across the continent, notably with German chemical giant, BASF, but also with the Swiss based infrastructure company SERSA. Network Rail will take delivery of 260 flex freight system® wagons in the 12 months from November last year, already with further superstructure options under consideration.

Photo: Wascosa AG

The obvious advantage over traditional dedicated wagons is that more types of cargo can be transported using fewer wagons which in turn can achieve more loaded journeys during their operating life cycle, ultimately meaning a more efficient utilisation of the wagon fleet as well as a lower investment risk.

By virtue of its adaptability the Wascosa flex freight system® also opens up the possibility of transporting two different types of cargo back and forth on a given route thus avoiding unproductive empty running which is a major cost factor in dedicated trainload configurations. Also, because of the intermodal capability of superstructures such as open boxes and ISO containers, this flex freight system® can serve non-rail connected, inner-city destinations, without the need for time consuming and problematic transhipment operations that would be required in the case of traditional rail wagons.

The Wascosa flex freight system® is also more productive because of its suitability to seasonal and cyclical fluctuations and also offers a better cost to performance ratio in terms of repairs and servicing. This is because the flex freight system® has a higher standardization of critical components making it easier and faster to maintain which in turn means less downtime and lost revenue because if the modular superstructure is damaged in any way it can simply be replaced without the whole wagon having to go to a repair shop.

Finally, it’s very easy and fast to change the superstructure module using a forklift / handler which minimises wagon downtime and eliminates the need for separate pools of single use wagons.

All in all, Wascosa’s flex freight system® is a smart way of carrying different types of cargo without essentially changing the wagon and forms part of the vision which has enabled Wascosa to progress from being the fourth largest wagon rental company on the continent to Europe’s first provider of freight wagon systems.

Find more information here:

www.wascosa.com

Video: Wascosa flex freight system

JAN KEISER

Head of Marketing & Communication

T +41 41 727 67 41

marketing@wascosa.com

MICK TINSLEY

Agent for UK & Eire

T +44 (0)7801 906013

mick.tinsley@wascosa.com