Innovationen

Weiterdenken ist unser Credo. Jedes Jahr kommen neue Lösungen und Patente hinzu, die schon heute die Anforderungen der Zukunft erfüllen. Wie Sie sehen, glauben wir nicht an Grenzen.

-

Details

WASCOSA safe tank car®

WASCOSA safe tank car®

Der WASCOSA safe tank car® setzt einen neuen Sicherheits-Massstab im Transport von Gefahrgut auf der Schiene. Eine erste Serie des WASCOSA safe tank car® wird für den Transport von Schwefeldioxid eingesetzt. Mit seinen verschiedenen Sicherheitselementen und den optimierten Übergangsbühnen an beiden Wagenenden verkörpert dieser Wagentyp den Gefahrgutkesselwagen der Zukunft. Gemeinsam mit dem Kunden, Güterwagen- und Komponentenherstellern, Know-how-Trägern der Crash- und Simulations-Technologie sowie nicht zuletzt dem deutschen Eisenbahn-Bundesamt wurde ein völlig neues Sicherheits- und Arbeitsschutzpaket entwickelt.

In der Ausschreibung des Kunden wurde ein voll ausgestatteter Chlorwagen gefordert, der im Bereich Sicherheit jedoch deutlich mehr bieten sollte als die bisher am Markt verfügbaren Wagen. Zusammen mit langjährigen Partnern, u.a. grossen Know-how-Trägern im Bereich der Entwicklung von Sicherheitskomponenten, wurde deshalb ein umfangreiches Sicherheitskonzept für den Gefahrgutkesselwagen erarbeitet. So wurde zum Beispiel ein völlig neuer, zum Patent angemeldeter Überrollschutz entwickelt. Ein weiteres Sicherheitselement sind die aus dem Lokomotivbau stammenden EST Suprapuffer G2. Das nach neuesten Erkenntnissen optimierte Kraftniveau und Deformationsverhalten dieser Puffer schützt den WASCOSA safe tank car® mit verstärktem Untergestell weit über das im RID geforderte Mass hinaus.

Um grössere Schäden bei Entgleisungen zu vermeiden, ist der Wagen mit zwei mechanischen Entgleisungsdetektoren ausgerüstet. Zusätzlich ist der WASCOSA safe tank car® mit vier Aufkletterschutz-Modulen Typ AC04 der Firma EST ausgerüstet, welche bei einem Unfall das Aufklettern der Puffer eines Wagens über die Puffer des benachbarten Wagens verhindern. Erstmals erfüllt dieser völlig neu konzipierte Überpufferungsschutz die RID-Sondervorschrift TE25 Absatz a), die nicht nur fordert, den Kesselboden vor dem Eindringen von aufkletternden Gegenpuffern zu schützen, sondern das Entstehen von Aufklettern bereits in der Anfangsphase zu verhindern.

Zur Arbeitssicherheit trägt eine optimierte Übergangsbühne mit durchgehend uneingeschränkter Arbeitsgangbreite und zusätzlichen Handgriffen am seitlichen Aufstieg bei. Wurde bei Neubau bisher nur ein Wagenende mit einer Übergangsbühne ausgestattet, so bietet der WASCOSA safe tank car® dem Betriebspersonal an beiden Wagenenden eine sichere Übergangs- und Mitfahrmöglichkeit.

Da Sicherheitselemente nur dann sinnvoll sind, wenn sie auch nachweislich die Sicherheit erhöhen, hat WASCOSA für den WASCOSA safe tank car® und alle seine Komponenten in Absprache mit den Zulassungsbehörden erstmals rechnerische Simulationen der unterschiedlichen Belastungsfälle durchführen lassen. Partner hierfür war die Firma Makross aus München, die seit Jahren erfolgreich Simulationsrechnungen für alle namhaften Automobilhersteller durchführt.

-

Details

Schüttgutwagen, 60m3, Fanps 2.0

Schüttgutwagen, 60m3, Fanps 2.0

Für den Transport von Gleisschotter

Vorteile

- Einstellung und Kontrolle der Position der Entladezylinder und -Trichter durch Funksteuerung.

- Schalldämmung von Entladezylindern

- Die 6 Entladezylinder werden über eine Funksteuerung bedient

- 360° Beleuchtung des Gleisschotterentladewagen durch 14 LEDs

- Wagen für den Transport von Kies und Schotter mit robustem Auslasssystem

-

Details

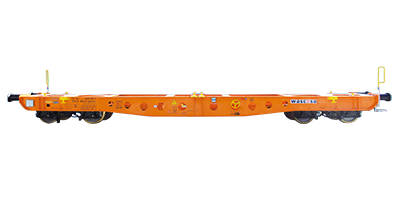

Wascosa flex freight system®, Containertragwagen 45', Sgmmnss

Wascosa flex freight system®, Containertragwagen 45', Sgmmnss

Für den Transport von intermodalen Ladeeinheiten. Bestandteil des WASCOSA flex freight systems®

Vorteile

- «5L» Tragwagen:

• Laufleistungsstark durch den Einsatz moderner Scheibenbremsen

• Besonders leise, nur 78 dB(A)

• Besonders leicht mit einem Eigengewicht von 16,5 t

• Life-Cycle-Cost orientiert, durch schnell austauschbare Komponenten

• Logistikfähig durch den Einsatz von Telematik - Wascosa flex freight system®: Transport verschiedener Güter durch die Kombination des besonders leichten Containertragwagens mit einem individuellen Oberbau

- Die Kombination des Wagens mit 45‘ Tankcontainern kann Kesselwagen ersetzen und ermöglicht eine unabhängige Instandhaltung beider Komponenten

- Transport von Tankcontainern im Einzelwagenverkehr mit bis zu 2,70 m Containerhöhe im G1-Profil

- «5L» Tragwagen:

-

Details

WASCOSA euro tank car®

WASCOSA euro tank car®

ALLGEMEINES Eigengewicht ca. 24.0 Tonnen Radsatzlast 22.5 Tonnen Zulässiges Gesamtgewicht 90.0 Tonnen Verkehrsgeschwindigkeit leer 120 km/h, beladen 100 km/h UNTERGESTELL Länge über Puffer 17.00 m Puffer Kategorie A, Typ MINER Drehgestell Y25 Lsd1 (BA 628) Radsätze BA 004 Bremse KE-GP 16", mit Umstellventil LB2 Zugeinrichtung Keystone Typ 540.5 TANK Tankwerkstoff 1.0570, S355J2G3, gem. EN 10025 TRT 042 Tankinhalt 95 m3 Tankcode L4BH Berechnungsdruck (RID) 10 bar Prüfdruck 4 bar Betriebsdruck max. 3 bar Explosionsstossfestigkeit (TRT 006) 8.7 bar Berechnungsdruck 0.4 bar Betriebsdruck des Tankes -20 °C / +50 °C FÜLL- UND ENTLEEREINRICHTUNG Dom 4-Knebeldom DN 500 Bodenventil BV 100 Typ Krombach (mechanisch) Seitenventil DN 100 Typ ADLER FA1 Spezial GASPENDELSYSTEM * Belüftungsventil BLV 100 Typ Koch/Kiel (mechanisch) Sicherheitsklappe DN 80, SV38 Typ Krombach Trockenkupplung Civacon 4" mit Deckel Vaterkupplung Elaflex 3" mit Deckel Vaterkupplung Elaflex 2" mit Deckel Anschluss DN 80 / 2" mit Deckel * Geistiges Eigentum der Wascosa, durch Patente geschützt.

-

Details

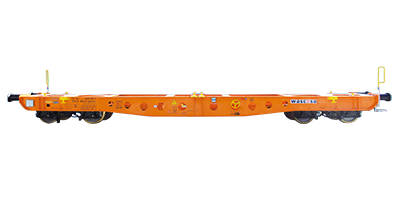

Wascosa flex freight system®, Containertragwagen 48', Sgmmnss

Wascosa flex freight system®, Containertragwagen 48', Sgmmnss

Für den Transport von intermodalen Ladeeinheiten, Bestandteil des WASCOSA flex freight system®

Vorteile

- «5L» Tragwagen:

• Laufleistungsstark durch den Einsatz moderner Scheibenbremsen

• Lärmarm

• Besonders leicht mit einem Eigengewicht von 16,0 t

• Life-Cycle-Cost orientiert, durch schnell austauschbare Komponenten

• Logistikfähig durch den Einsatz von Telematik - Wascosa flex freight system®: Transport verschiedener Güter durch die Kombination des besonders leichten Containertragwagens mit einem individuellen Oberbau

- Die Kombination des Wagens mit 45‘ Tankcontainern kann Kesselwagen ersetzen und ermöglicht eine unabhängige Instandhaltung beider Komponenten

- Transport von Tankcontainern im Einzelwagenverkehr mit bis zu 2,70 m Containerhöhe im G1-Profil

- «5L» Tragwagen:

-

Details

Wascosa flex freight system®, Containertragwagen 52', Sgmmns

Wascosa flex freight system®, Containertragwagen 52', Sgmmns

Für den Transport von intermodalen Ladeeinheiten, Bestandteil des Wascosa flex freight system®

Vorteile- Wascosa flex freight system®: Transport verschiedener Güter durch die Kombination des besonders leichten Containertragwagens mit einem individuellen Oberbau

- Die Kombination des Wagens mit 45' oder 52' Tankcontainern kann Kesselwagen ersetzen und ermöglicht eine unabhängige Instandhaltung beider Komponenten

- Transport von Tankcontainern im Einzelwagenverkehr mit bis zu 2,70 m Containerhöhe im G1 Profil

-

Details

WASCOSA flex freight system® mit Wechselaufbau Timber-Kassette

WASCOSA flex freight system® mit Wechselaufbau Timber-Kassette

WASCOSA hat sich zum Ziel gesetzt der fortschrittlichste Güterwagenvermieter zu sein. Daraus ergibt sich die Verpflichtung, höchsten Kundenansprüchen zu genügen und stets neue Impulse in der Güterwagenbranche zu setzen. Das WASCOSA flex freight system® wurde speziell für diejenigen Teilnehmer am Schienengüterverkehr entwickelt, welche die langfristige Produktivität und Wirtschaftlichkeit ihres eingesetzten Rollmaterials erhöhen und die Anzahl der eingesetzten Güterwagen optimieren möchten. Ziel des Projektes war es, einen Güterwagen zu entwickeln, der für unterschiedliche Arten von Ladegütern ganzjährig eingesetzt werden kann und somit über den gesamten Life Cycle des Wagens hinweg eine kontinuierlich hohe Beschäftigung und ebenso hohe Produktivität ermöglicht.

Ausgangspunkt war der Umstand, dass viele EVU’s Spezialgüterwagen einsetzen, die nur für ein bestimmtes Ladegut verwendet werden können und somit bei schwankender Nachfrage zu unbefriedigenden wirtschaftlichen Ergebnissen führen, einerseits durch ungenügende Auslastung, andererseits durch zahlenmässig überhöhte Wagenparks. Zusätzlich dazu fallen auch die Abstellgebühren ins Gewicht.

Das Konzept des WASCOSA flex freight system® wurde pünktlich zur transport logistic Messe 2009 in München fertig gestellt und basiert auf zwei Elementen. Das Basiselement ist ein vollwertiger 60‘ Containertragwagen, der jederzeit uneingeschränkt für den Transport aller möglichen Behälter des kombinierten Verkehrs eingesetzt werden kann. Darüber hinaus verfügt der Containertragwagen über spezielle, zusätzliche Befestigungsmöglichkeiten für die Anbringung eines Spezialgüterwagenaufbaus. Diese machen den Wagen zu einem exklusiven Fahrzeug mit einem entsprechenden Mehrwert für die Verlader.

Das zweite Element des Konzepts besteht aus unterschiedlichen Aufbauten, die eine Umnutzung des Wagens je nach Bedarf und Ladegut zu einem Spezialgüterwagen ermöglichen.

Weitere Aufbauten befinden sich derzeit in der Entwicklung und werden laufend eingeführt. Für das WASCOSA flex freight system® wurde Patentschutz angemeldet.

Ansprechpartner

Frau Irmhild Saabel,

Leiterin Business Development / Mitglied der Geschäftsleitung

T +41 41 727 67 62, F +41 41 727 67 77,

M +41 79 330 89 89, irmhild.saabel@wascosa.ch -

Details

Wascosa flex freight system®, Containertragwagen 54', Sgmmns

Wascosa flex freight system®, Containertragwagen 54', Sgmmns

Für den Transport von intermodalen Ladeeinheiten, Bestandteil des Wascosa flex freight systems®

Vorteile

- Wascosa flex freight system®: Transport verschiedener Güter durch die Kombination des besonders leichten Containertragwagens mit einem individuellen Oberbau

- Die Kombination des Wagens mit 45‘ oder 52‘ Tankcontainern kann Kesselwagen ersetzen und ermöglicht eine unabhängige Instandhaltung beider Komponenten

- Transport von Tankcontainern im Einzelwagenverkehr mit bis zu 2,70 m Containerhöhe im G1-Profil